In randomly selecting 50 of our household items, including kitchenware, appliances, clothing, and electronics, only four items were made in the USA. All others were outsourced overseas. However, my three snowshoes were made here in the United States. My Redfeather and Northern Lites snowshoes were both produced in Wisconsin. My Country Ways Ojibwe wood-frame snowshoe kit I weaved is from Minnesota.

Be it snowshoes, or any product, United States (U.S.) manufacturing companies experienced a significant snag in their production and sales beginning in March 2020 due to a national and global shutdown due to the Covid-19 pandemic. Consequently, supply chain slowdown and workforce shortages exacerbated the situation. Interestingly, companies making snowshoes in the U.S., in general, seemed to do well in producing and getting products to consumers on time.

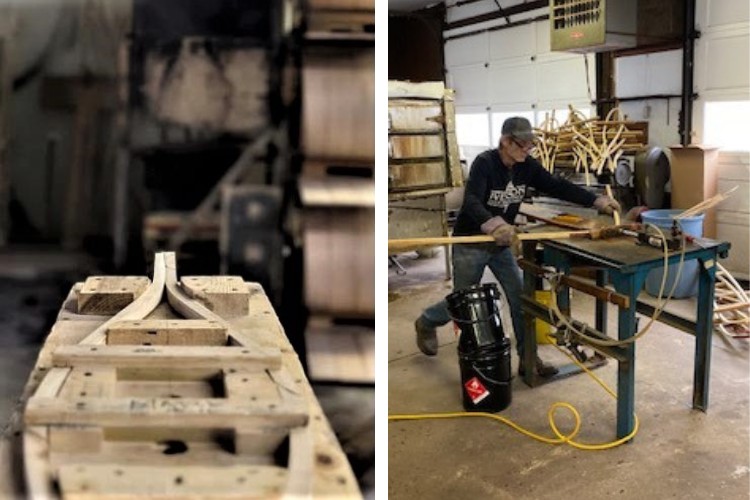

Outdoor recreation exploded during the pandemic. Pictured here is the machinery that shapes US-made Redfeather Snowshoe aluminum frames. Photo: Andrew Vittone, Redfeather Snowshoes- ORC Industries

Some of the links in this article may contain affiliate links. When you purchase using these links, part of the proceeds go to Snowshoe Mag. Additionally, as Amazon Associates, we earn from qualifying purchases. Please see our disclosure for more details.

Pandemic Impact on Outdoor Recreation

Let’s first look at the impact the pandemic had on outdoor recreation. It exploded! People went outdoors in groves to get out of the house and to social distance. An Outdoor Industries Association (OIA) statement dated August 2020 reads, “Americans have flocked to outdoor recreation amid COVID restrictions, as the data from OIA indicates.” The report continues, “Americans took up new activities in significant numbers in April, May, and June of 2020.”

“In 2020, 53% of Americans ages six and over participated in outdoor recreation at least once, the highest participation rate on record,” according to OIA’s 2021 Outdoor Participation Trends Report. They also stated, “Driven by COVID impacts, 7.1 million more (people) participated than in 2019.”

Interestingly too, Snowshoe Magazine’s highest readership traffic ever was in the winter of 2020-2021, three times the growth from 2019-2020, according to Susan Wowk, the editor. Getting out on snowshoes apparently was an outcome of the pandemic. Jim Baker of Iverson Snowshoes, manufactured in the Upper Peninsula of Michigan, stated, “We heard from many of our customers who were grateful for discovering a way to stay active (snowshoeing) in northern climates and to engage in some level of socialization outside activity.”

With increased outdoor participation came an increase in consumer purchasing of outdoor products such as bicycles, camping gear, fishing gear, water sports equipment, and much more…when you could get them, of course. Snowshoes were no exception.

The COVID-19 pandemic significantly impacted the manufacturing, sales, and delivery of those outdoor recreation products. For quite a while, customers had to wait to purchase their chosen outdoor product. Stores were just unable to get the merchandise in so much demand.

Read More: Reap the Health Benefits of Snowshoeing

The COVID-19 pandemic had a major impact on the manufacturing, sales, and delivery of those outdoor recreation products. Snowshoe assembly is in progress, made in the USA by Northern Lites. Photo: Wes Dunn, Northern Lites

The Supply Chain Situation

Understanding the supply chain slowdown following the pandemic onset is complex. In a nutshell, the recent supply chain crisis took off during Covid-19, beginning with the U.S. lockdown (and much of the planet too). The shutting down of factories, ports, trucking, and more slowed the manufacturing and delivery of products. The process of producing goods and getting them to the consumer broke down. Then came a high demand by U.S. consumers and a federal stimulus check that promoted spending. A bottleneck occurred, putting stress on the global supply chain.

But many factors contributed to the ongoing supply chain disruptions in the U.S. during and after the pandemic hit. The labor shortages in trucking, warehousing, and distribution centers, cargo ships stalled in and near U.S. harbors unable to unload materials, global limitations on air and rail freight, material shortages for manufacturing, the Russian/Ukraine war, China’s Covid lockdown…all contributed to consumers having difficulties getting goods on time.

So, how did all that impact the U.S. snowshoe manufacturing industry? How did snowshoes made in the U.S. do okay at that time? Well, let us see.

Snowshoes Made Abroad or at Home

Large US snowshoe companies such as Tubbs, Atlas, Yukon Charlie’s, and Crescent Moon snowshoes outsource their manufacturing elsewhere – primarily in China. But do not discount the quality of their snowshoes since it appears China makes quality outdoor products, including snowshoes. Those USA snowshoe companies that outsource seemingly do so to reduce costs to sell their product at a lower price to consumers.

U.S. companies who manufacture their snowshoes at home strive to keep a “Made in USA” tradition alive while producing a quality product. They maintain an at-home pride while providing local jobs.

By connecting with three modern companies that manufacture snowshoes in the U.S. (Northern Lites, Redfeather, and Dion-NeviTREK), and three traditional companies (Iverson, Wilcox and Williams Country Ways, and Northern Toboggan Company), they were for the most part able to get materials and parts (despite the supply chain slowdown) and assemble the snowshoes here in the States. Although some companies experienced difficulties, for the most part, they reasonably met supply demands, and they persevered through the pandemic.

Modern snowshoes include aluminum frames, plastic, metal, and foam. Traditional snowshoes have frames crafted of wood.

Read More: Traditional Wooden Snowshoes: Shapes, Designs, and Names

With the slowdown in the supply chain, some companies making their snowshoes in the USA were well prepared during challenging times. Here, Ross Richards places cleats at Dion Snowshoe Company. Photo: Greg Nesbit – Bennington, Vermont

Good Planning and Supplies Secured Domestically

Since the onset of the pandemic and the slowdown in the supply chain, some companies making their products in the U.S. felt well-prepared during tough times. Redfeather Outdoors., with snowshoes crafted by hand in La Crosse, Wisconsin, at ORC Industries, showed preparedness. Andrew Vittone, their director of sales and marketing, stated in this regard, “Our supply chain has been good. We planned well and purchased knowing there would be issues coming down the pipeline.”

Many USA snowshoe companies were in a good position because they were getting supplies locally. Joanne Petrozzi-Jones, the owner of NeviTREK, a snowshoe company that merged with Dion Snowshoes and moved from New York to Vermont, says, “The pandemic didn’t have much effect on our manufacturing because we typically buy (materials and parts) from U.S. companies. The big advantage is that we don’t have to worry about getting materials in time for our production needs.”

Read More: Your Go-To FAQ for Dion-NeviTREK Snowshoes

At-Home Consequence

The owners of Crescent Moon recently bought Northern Lites Snowshoe Company, now based in Colorado. Northern Lites appears to have done very well in the long run. Wes Dunn, new co-owner, says, “We were able to produce many more snowshoes in 2022 vs 2021 and 2020. At least double.”

Jim Baker of Iverson Snowshoes felt relieved that their sales were good during this challenging time. “We have enjoyed incremental sales growth before, during, and after the pandemic with a bit of a bump during the period of the pandemic,” says Baker. He continues, “We have a small production team. During the pandemic, production declined a little bit as a result of mandatory closures.”

Northern Toboggan Company (NTC), a Minnesota manufacturer of toboggans and snowshoes, also did well. NTC’s Jackson Harren reported, “During the 2020-21 Seasons, we saw growth in the direct-to-customer sales of our products across the board, as more people ventured outside.”

NeviTREK’s Petrozzi-Jones noted, “Our biggest year was 2021. Our production rate increased.” COVID did not impact them negatively. Petrozzi-Jones continues, “It (the pandemic) happened shortly after we merged NeviTREK with Dion. When we went back to work, we tried to catch up on production. The 2020-21 winter season had an unexpected surge in orders. The 2021-2022 winter continued with many orders, but not as much as the previous season.”

Consequently, for Redfeather, Vittone states, “We doubled our production during the pandemic to cover the demands of our dealers. During the high points of the pandemic, snowshoes were flying out the door as soon as they were packed up in the production line.”

Read More: Top 10 Snowshoe Tips for First-Timers

Many companies’ sales did well during the pandemic. L: A traditional snowshoe frame by Northern Toboggan Company. Photo: Jackson Harren, Northern Toboggan Company R: Ken Holmes crafts Upper Peninsula of Michigan made Iverson Snowshoes. Photo: Jim Baker, Iverson Snowshoes

At-Home Difficulties

Some companies making snowshoes in the U.S. faced difficulties. Dunn of Northern Lites shared, “2022/2023 is our first year manufacturing Northern Lites snowshoes. I would say from conversations with the previous owners that COVID-19 really put a huge hamper on their production. Much of it due to supply chain issues that caused production bottlenecks and staffing shortages.”

A traditional snowshoe company experienced a drop in sales since their primary customers closed during the onset of the pandemic. Greg Wilcox of Country Ways out of Minnesota manufactured traditional snowshoes and snowshoe kits. Wilcox reported, “Country Ways sales were 60-70% wholesale to groups like schools, nature and environmental centers, and state and national parks. Those group sales went to nothing during the winter of 2020-21 with the Covid shutdown.” The good news, however, is that although kit sales were lost at that time, finished snowshoe numbers thrived. “Our finished number actually grew. Our increased profit on retail vs. wholesale kept us going,” says Wilcox.

Impacts by Supply Chain

The supply chain slowdown appears to have affected snowshoe companies that outsource overseas. Vittone of Redfeather noted, “Our main competition relied on foreign manufacturing. This caused a lot of delays. They had to deal with the mess that was at U.S. ports. Most of their dealers did not receive their preseason order until March (2021), which was too late.”

And the supply chain crisis did not impact Northern Lites, where it seemed it may have affected other companies. “We did not have to worry as much about terrible container rates or lead times for supplies coming over from Asia, where many of our competitors source their snowshoes,” Dunn says.

The supply chain issues did not impact traditional producers. Northern Toboggan Company got their materials near home. Harren reported, “We have a lot of control over the supply chain and the production process by having most all of it local.” He continues, “We source our wood and most other materials locally, so we were able to keep in good communication with each vendor and the sawmills.”

Regarding Country Ways, Wilcox stated, “We were fortunate that we did not have any issues with supply. Having multiple vendors and ordering extra kept us out of any issues with parts.” They were concerned about white ash availability for their snowshoes and kits. However, it had nothing to do with the pandemic but rather the emerald ash borer infestation. In October 2022, NTC bought Country Ways. Harren expressed delight with acquiring this well-established product and continues communication with Greg Wilcox in their transition.

Iverson Snowshoes were not concerned about supply chain slowdowns because they had ample supplies to meet a minimum order. Baker found it “a blessing in disguise when supply chains backed up, as we had enough materials on hand to make it through the backups and long waits.” Also, Iverson Snowshoes buys their logs locally and has a local portable sawmill cut the wood into slabs. In this respect, Baker says, “We are somewhat isolated from industrial supply chain issues.”

Read More: A Few U.S. Artisans Keep Traditional Snowshoes a Tradition

One advantage to being U.S. made is a quick turnaround for special orders. Here, Dion-NeviTREK places its logo onto its US-made snowshoe. Photo: Greg Nesbit – Bennington, Vermont

USA-Made Snowshoes Advantages

So, what is a big advantage of snowshoes made in the U.S.? As stated by Petrozzi-Jones, “Many of our customers buy from us because we are still made in the U.S.” Yes, some folks prefer products made at home rather than abroad. There are other advantages, as she says, “We are also able to provide a quick turnaround for snowshoe repairs or last-minute requests for parts or special orders.” But in the long run, Wilcox tops it off by noting, “Customers know when they call, a real person answers the phone to help.”

Regarding the manufacturing process, Petrozzi-Jones said, “The big advantage is that we don’t have to worry about getting materials in time for our production needs.” Companies that secure their materials within the country have an advantage in keeping their production in progress. Vittone noted, “The advantages were clear – because we manufactured our own snowshoes here in Wisconsin, we had full control of the process and could build to fit the need of our customers.”

Our traditional companies find that using lumber from home and using local suppliers for parts is a big advantage to producing in the U.S. Baker describes, “Being in the U.S. keeps us close to the lumber source. We buy exclusively from U.S. suppliers who understand our company and our mission.” Harren also supports that notion: “Our quality and craftsmanship are unmatched in the industry, and our relationships with suppliers are strong. This is best accomplished in America.”

Overall

Although most of the materials in my home are made elsewhere, my snowshoes are a product of the USA. This has been to my advantage since the quality of my Redfeather, Northern Lites, and Country Ways Ojibwe snowshoes are exceptional. They most likely will outlive me. Hopefully, at that point, my descendants benefit from them when I am long gone. However, I am in no hurry for that to happen.

Read Next: Snowshoe Makers and Manufacturers That Were

Leave a Comment